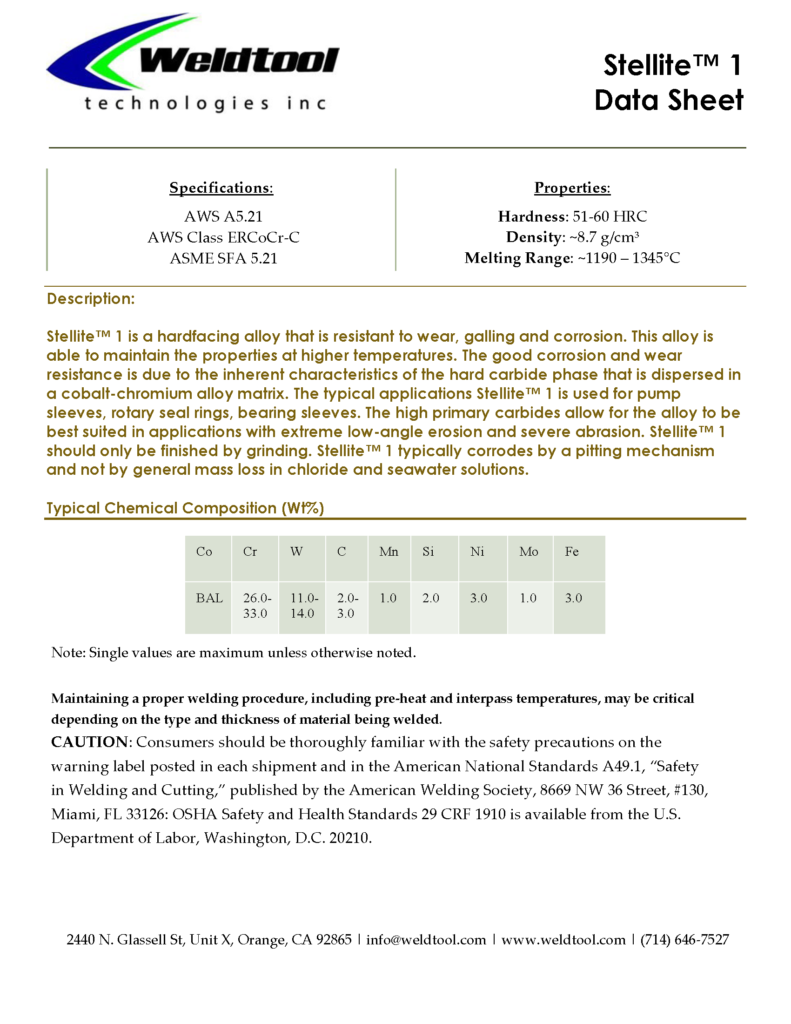

Specifications:

AWS A5.21

AWS Class ERCoCr-C

ASME SFA 5.21

Description:

Stellite™ 1 is a hardfacing alloy that is resistant to wear, galling and corrosion. This alloy is able to maintain the properties at higher temperatures. The good corrosion and wear resistance is due to the inherent characteristics of the hard carbide phase that is dispersed in a cobalt-chromium alloy matrix. The typical applications Stellite™ 1 is used for pump sleeves, rotary seal rings, bearing sleeves. The high primary carbides allow for the alloy to be best suited in applications with extreme low-angle erosion and severe abrasion. Stellite™ 1 should only be finished by grinding. Stellite™ 1 typically corrodes by a pitting mechanism and not by general mass loss in chloride and seawater solutions.

Properties:

Hardness: 51-60 HRC

Density: ~8.7 g/cm3

Melting Range: ~1190 – 1345°C

Chemical Composition (Wt%):

Note: Single values are maximum unless otherwise noted.

Co Cr W C Mn Si Ni Mo Fe

BAL 26.0-33.0 11.0-14.0 2.0-3.0 1.0 2.0 3.0 1.0 3.0