Specifications:

Alloy 4643

AWS A5.10

ER4643

AMS 4189

UNS A94643

USWC 4189(C)

Description:

Aerospace Material Specification 4189 covers aluminum alloy 4643 in the form of welding wire. Typically used as a filler metal in gas-metal-arc or gas-tungsten-arc welding applications of similar composition to produce joints of low dilution.

A primary use is in the welding of heavy sections of certain aluminum alloys when multiple weld passes are used and dilution of the base metal into the puddle is negligible. This alloy could also offer advantages in brazing type applications on thin sections where dilution ratios are low.

Alloy 4643 is similar in weldability to 4043. The weld cracking characteristics, flow, pre-cleaning and machine settings are the same for this alloy as for 4043. The corrosion resistance is very good and equals or exceeds alloy 4043 in the weld zone and heat affected regions

Available in multiple diameters and sizes in straight length wire and in spools

4.1si 0.20mg

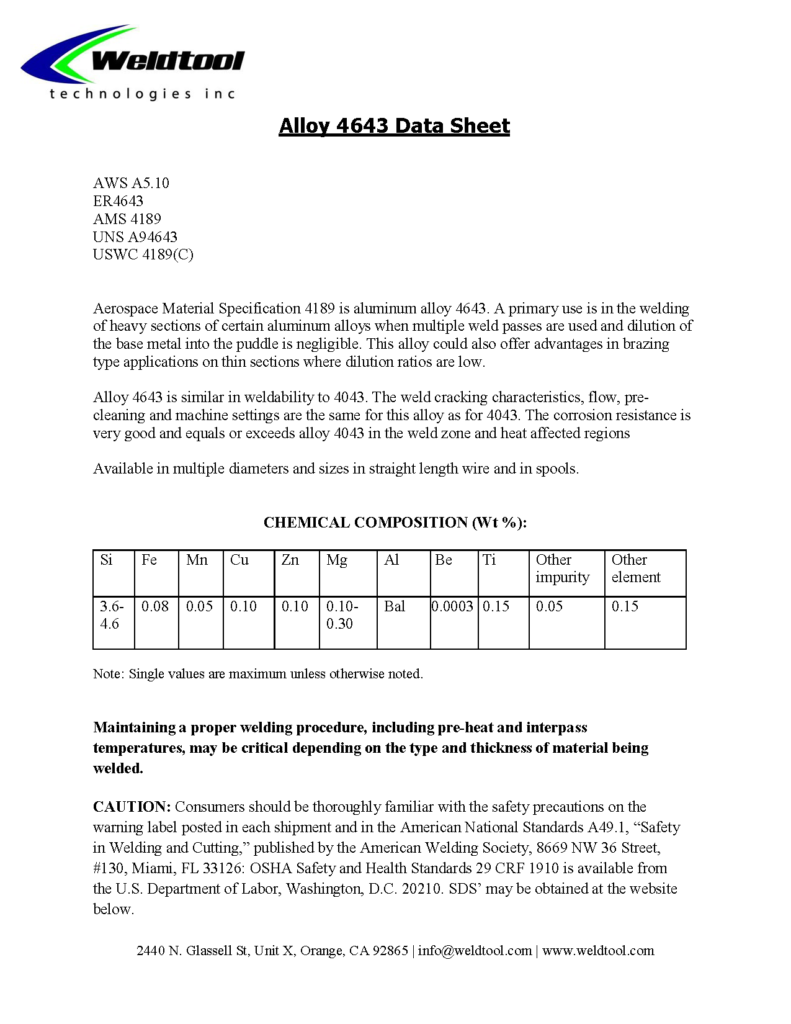

Chemical Composition:

Note: Single values are maximum unless otherwise noted.

Si Fe Mn Cu Zn Mg Al Be Ti Other impurity Other element

3.6-4.6 0.08 0.05 0.10 0.10 0.10-0.30 Bal 0.0003 0.15 0.05 0.15